Natural Bamboo Flooring Horizontal UV Coated Floor

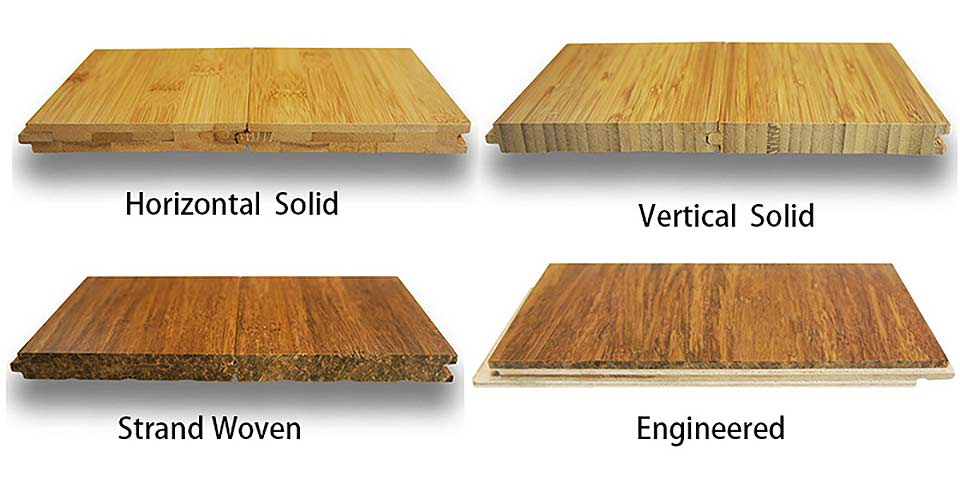

Bamboo flooring grain types

Bamboo flooring is made from the local high quality Mao bamboo. It came into being after thirty processing as bleaching, dehydrating, hot-pressing, etc. So it has the character of mothproof antiseptic, and non-deforming. The bamboo flooring is an ideal decoration for hotel, office and home supply. When it comes to different grain types of bamboo, there are three main choices: horizontal, vertical, and strand-woven. Each one has different characteristics that will help buyers decide which type of bamboo to purchase and install in their home or business. The grain type to purchase depends greatly on the overall look the buyer is trying to achieve.

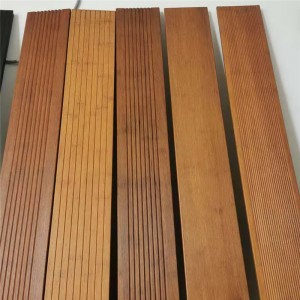

Natural and Carbonized Bamboo Flooring

Along with choices in style you may wish to consider in bamboo flooring, there is also the question of color. Bamboo flooring is available in two colors – natural and carbonized. The color is determined at the boiling process. Natural bamboo appears in a creamy blonde color that is known to add a touch of brightness to an interior. Carbonized bamboo is characterized by its smoky, caramel hue which is the result of a longer boiling process which causes the remaining starches in the bamboo to caramelize. It should be noted that by the end of the respective boiling processes, the natural remains to be the slightly harder bamboo flooring. The carbonization process which defines carbonized bamboo reduces the bamboo’s hardness by about 30%. It must also be noted that even though this is true, both colors of bamboo flooring can still be classified as being as hard as some hardwood species.

| Product | Horizontal Natural Bamboo Flooring |

| Material | 100% bamboo |

| Coating | 6 coating finish ,2 top UV coating |

| Finish | Klump aluminum Oxide/Treffert Acrylic System |

| Surface | Bleached natural |

| Formaldehyde Emission | up to E1 standard of Europe |

| Plank Moisture content | 8-10% |

| Function | Durable,Anti-abrasion,sound-proof,Insect-free,moisture proof,eco-friendly |

| Certificate | CE, ISO9001,ISO14001 ,BV, FSC |

| Residential warranty | 25 years of structural guarantee |

| Delivery | Within 15-20days after receipt of 30% deposit or L/C |

| MOQ | 200 square meters |

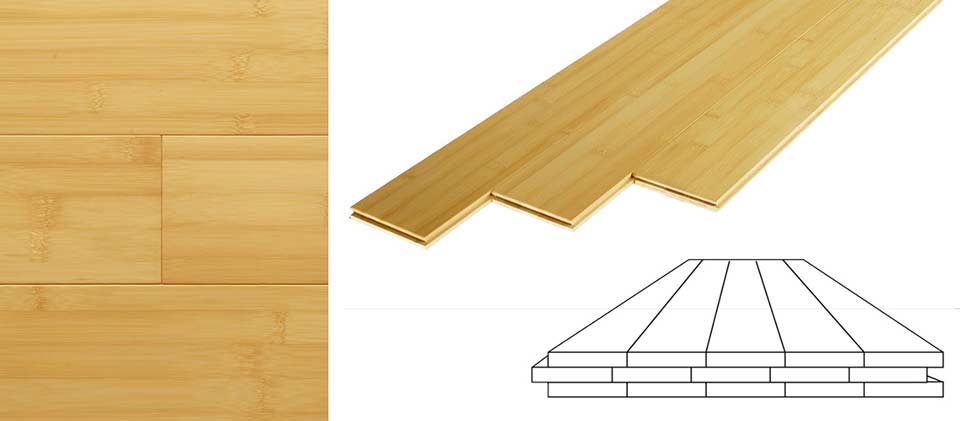

| Horizontal Natural bamboo flooring Technical Data | |||

|

Size |

960×96×15mm 、1920×96×15mm | ||

|

Surface Treatment |

varnish(3 options------Matte \ Satin \ Glossy) | ||

|

Joint(2 options) |

Tongue & Groove |

|

|

|

Click lock system |

|

||

|

Density |

660kg/m³ | ||

|

Weight |

10kg/㎡ | ||

|

Moisture Content |

8%-12% | ||

|

Release of formaldehyde |

0.007mg/ m³ | ||

|

Installation method |

Indoor, float or glue | ||

|

Carton size |

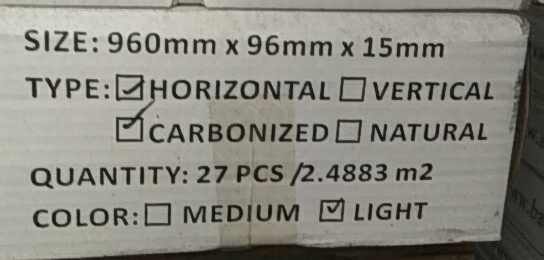

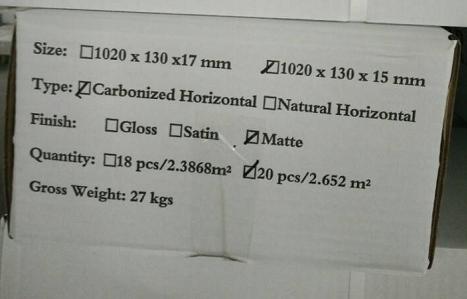

960×96×15mm |

980×305×145mm | |

|

1920×96×15mm |

1940×205×100mm | ||

|

Packing |

960×96×15mm |

With Pallets |

27pcs/ctn/2.4883㎡, 56ctns/plt, 9plts, 504ctns/1254.10㎡ |

|

Cartons Only |

27pcs/ctn/2.4883㎡, 700ctns/ 1741.81㎡ | ||

|

1920×96×15mm |

With Pallets |

12pcs/ctn/2.2118㎡, 50ctnsx 6plts, 60ctnsx 6plts, 12plts,660ctns/1459.79㎡ | |

|

Cartons Only |

/ | ||

Products Pictures

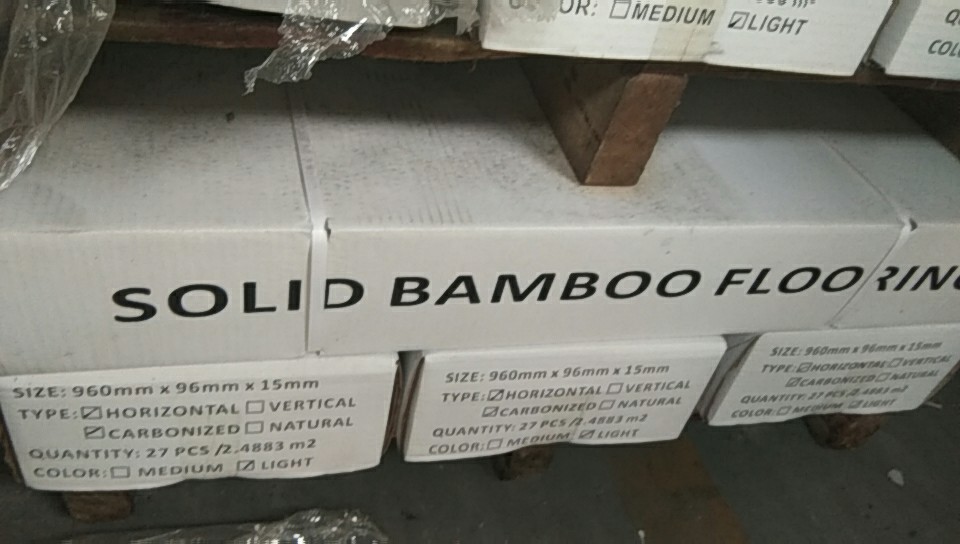

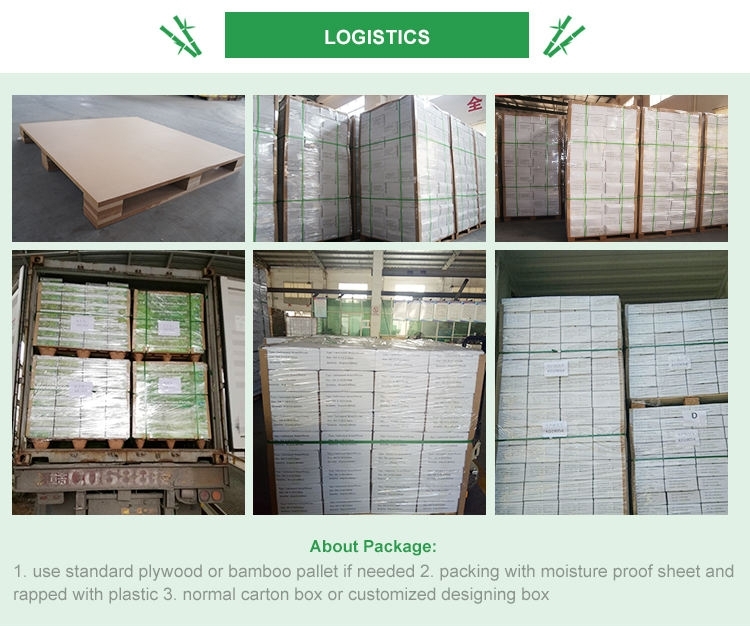

Packing Pictures

Care and Maintenance for bamboo flooring

• It is recommended that you use felt pads under chairs and furniture (a plastic mat should be used with office chairs on wheels) Solid bamboo floorings will mark with use, which add to its character.

• Rubber based castor cups should be used for heave load furniture such as armchairs and pianos.

• Doormats should be used inside and outside of all external doorways to prevent grit from being carried across the floor, protecting the surface from excessive wear and tear.

• For regular cleaning a damp cloth is advised. (We recommend that cloths be rung until no more drips are present before wiping the floor)

• A cap full of a suitable bamboo & real wood floor cleaner in a bucket of lukewarm water will help to restore your floors luster. Stubborn marks can be easily removed.

• Do not use abrasive cleaners, steel wool or scouring powder as this may damage the surface of your floor.

• Once or twice a year apply a suitable flooring polish to promote effective protection of the surface of the lacquer.

Once the lacquer has been damaged it is advisable to sand and re-lacquer the entire floor to maintain an even finish rather than spot lacquering. This is a procedure which is best carried out by a professional. Please note that repeated sanding will remove some of the textured finish.